From the Disk Brush to the "Contral Brush", a Dr. Gansow Innovation Story

More than half of the production and sales volume of scrubber-driers relates to the small configurations with only one disc brush and up to 21 "Ø brush plates. Their compactness, maneuverability, higher surface coverage and the lower entry price creates a high level of popularity amongst users and often replaces a manual method with equipment such as a scrubber, mop and press in their first investment step.

Use of a twist-free brush system

That's why the Dr. Gansow research approach relates on inventing a "twist" free brush system for sin-gle-disc brush heads. It culminated in the German Patent DBP 195 22. Otherwise the operator continu-ously has to operate against a tiring counter steering, and that leads from time to time to an unpleasant accumulation of collision events with furnishings within buildings. Here it was and is necessary to reme-dy the situation. Cylindrical brush systems were not in the systemic focus of Dr. Gansow: The research focused on an intensive, effective and residue-free cleaning of non-textile floor coverings and not at a wet sweeping analogous to sweeping machines adopted to dry materials.

The approach in the search for twist-free alternative solutions for the common disc brushes was and is the decoupling on two mechanically superimposed and opposing planes.

Das Contral™-Bürstensystem

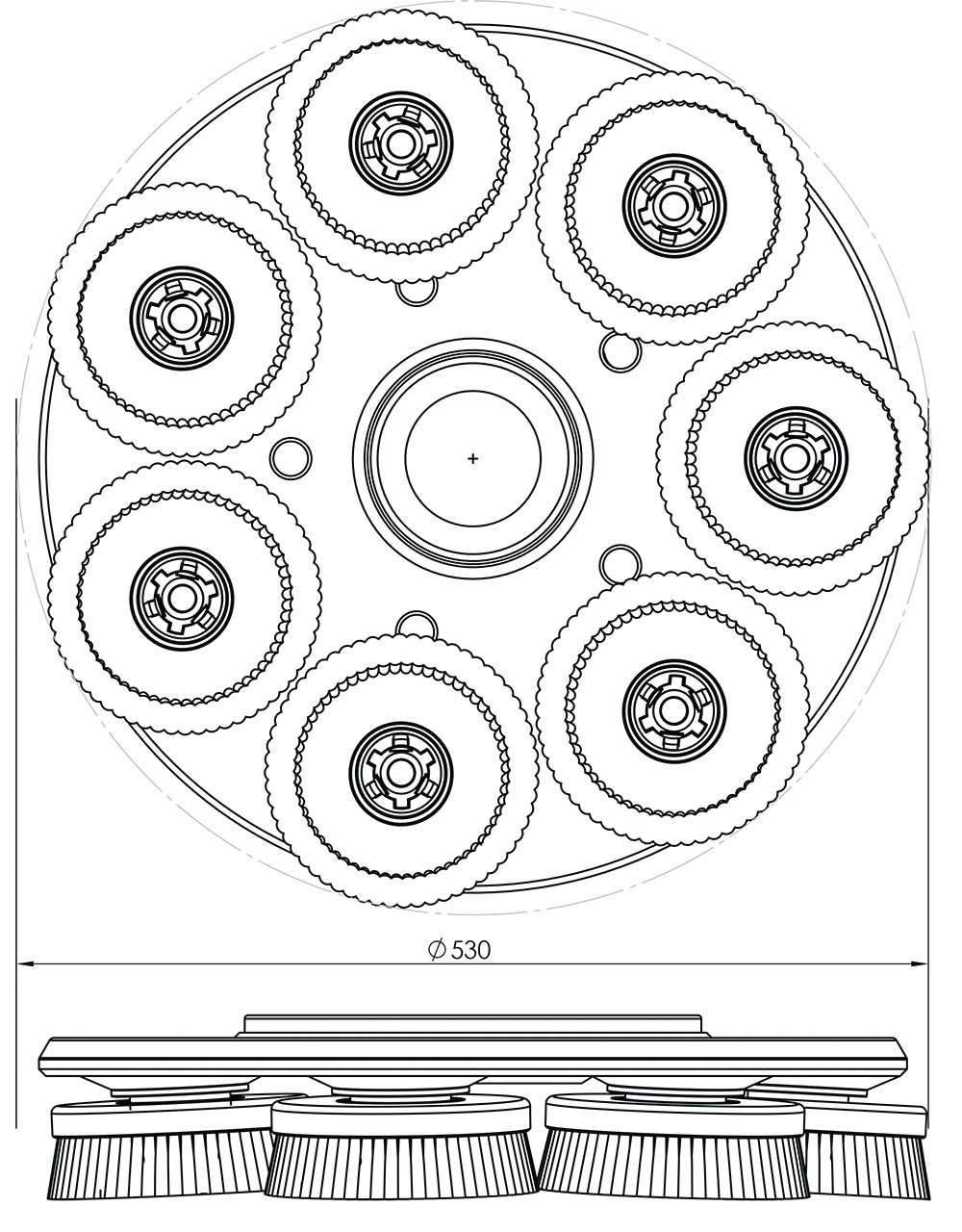

The first and highest level is a smooth upper brush plate with central bayonet coupling for horizontal and vertical guidance and power transmission. On the side facing the ground surface, small sub-brushes are arranged so that they are rotatable guided vertically and laterally backlash-free as well as in contrasting manner via ball-bearing vertical plug-in axes with vertical clip couplings.

Slanted sub-brushes cause contrarotation

The slight inclination (just 3°) of the plug-in axles towards the center, describing the coat of a cone, the dragged, friction-induced contra-rotation to the upper "master plate" of the smaller numerous sub-brushes, determine the so called "Contral Effect" (lateral contra rotation leads to the trademark "Contral"):

- the size ratios of the effective radii from a large radius of the sub-axes in the master plate

- compared to the smaller of the sub-plates effect

- a desired speed increase

- in the ratio of the radii minus a certain slip of perhaps 5-10%

- to an increasing speed level,

- which is able to trigger a quadratic-growing cleaning effect.

The cleaning power/energy of a tool, i.e. a brush or pad, is physically determined and effected by contact pressure and rotational speed, where the relevant formula of the kinetic energy is as follows: Ek = ½ m Δv² (Ek = kinetic energy, m = mass / pressure, Δv = speed change)

Here, the double effect of the research result of the “Contral Brush” plates becomes immediately apparent:

- The combination of opposing, twist canceling rotation combined

- with a quadratic efficiency on the cleaning force/intensity speed increase.

For a master plate of 21" or about 533mm diameter, the lower seven sub-brushes have a diameter of only 6" or about 150mm. The ratio of the effective radii is slightly lower, because the stub axles move a little from the edge of the master plate inward to ensure a solid composite of the mounting system of the plug-in axles of double helical bearings made of stainless steel in the edge region of the master plate. 6" is a standard diameter for pad systems, all of which are manufactured in the same way as tube sizes. The reason for this lies in the market introduction of the American 3M conglomerate followed by the company Glitt, also USA-derived.

For a master plate of 21" or about 533mm diameter, the lower seven sub-brushes have a diameter of only 6" or about 150mm. The ratio of the effective radii is slightly lower, because the stub axles move a little from the edge of the master plate inward to ensure a solid composite of the mounting system of the plug-in axles of double helical bearings made of stainless steel in the edge region of the master plate. 6" is a standard diameter for pad systems, all of which are manufactured in the same way as tube sizes. The reason for this lies in the market introduction of the American 3M conglomerate followed by the company Glitt, also USA-derived.

Service & Distribution

Do you have questions about our products or do you need help? We will be happy to assist you.